Versatile, high quality replacement in many tyre compounds

BBC grades have been validated as versatile replacements for multiple furnace carbon black grades used in tyres, offering technical performance benefits in several application areas. Their uniquely broad primary and aggregate particle size distributions provide a much larger degree of versatility compared to any individual furnace grade.

For tyre applications, we manufacture two grades that prove a versatile, one-to-one replacement for a wide range of current grades; BBC T30 and BBC T30S.

>> BBC T30

BBC T30 acts as a one-to-one replacement for N330 and N660 providing comparable hardness and a unique balance of mechanical and dynamic reinforcing characteristics. Concretely this means:

- High mechanical reinforcement as defined by tensile properties, abrasion and tear resistance comparable or better than N330

- Better dynamic performance than N660 as defined by low tan delta, very low hysteresis, Payne effect and lower rolling resistance

In addition, its versatility allows to selectively substitute N326, N347, N550 and N762.

>> BBC T30S

We have maximized the amount of silica in our BBC T30S to provide several differentiating benefits:

- Improves tear strength and abrasion resistance

- Receptive to silane-coupling for optimum mechanical/dynamic reinforcement

- Reduces hysteresis and lowers rolling resistance

- Improves wet grip

- Enhances rubber-to-metal bond strength

- Reduces electrical conductivity; especially valuable in applications where higher electrical resistivity is required.

>> Click below for more detailed information on use of our carbon blacks in:

>> User recommendations for substitution

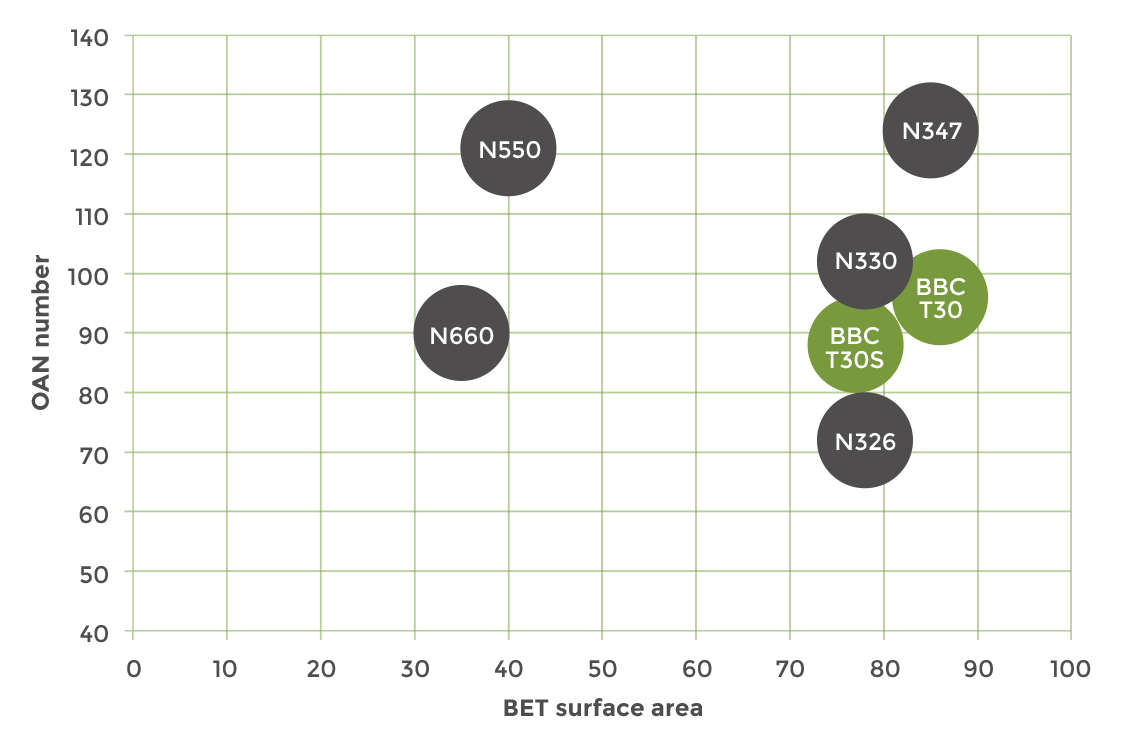

The hardness/modulus contribution of carbon black grades are closely correlated to their structure (OAN number). Like the Black Bear grades, N326 and N660 are also low structure grades and therefore allow for a very close 1:1 substitution possibility.

The figure on the right provides a general substitution guideline for compounding with equal hardness.

| Carbon Black grade | Loading (PHR) for comparable hardness |

|---|---|

| BBC T30(S) | 100% |

| N326 | 98% – 103% |

| N330 | 100% – 105% |

| N550 | 110% – 115% |

| N660 | 98% – 103% |

| N772 | 75% – 85% |

| N990 | 60% – 70% |