Black Bear opportunity: Improve key dynamic performance factors such as compression set and flex fatigue whilst either maintaining or improving mechanical performance factors (strength, durability)

>> Important performance criteria when designing an industrial rubber hose recipe design

(influenced by choice of carbon black)

- Abrasion/cut/tear resistance

- Thermo-chemical resistance (e.g. resistance to swelling)

- Flexibility (compound modulus) and flex fatigue

- Ply-adhesion to steel and textiles (e.g. influence on tack, cure-rate, etc.)

- Processability (e.g. influence on rheology, die-swell, etc.)

- Compression set to ensure effective sealing hose to connectors

- Low PAH (PAHs are mostly brought into a recipe by type of plasticiser and carbon black)

Generally, semi- and high- reinforcing blacks are used for hose compounds in order to ensure and optimise the various performance requirements described above. This provides various opportunities for Black Bear grades with the objective of adding technical value.

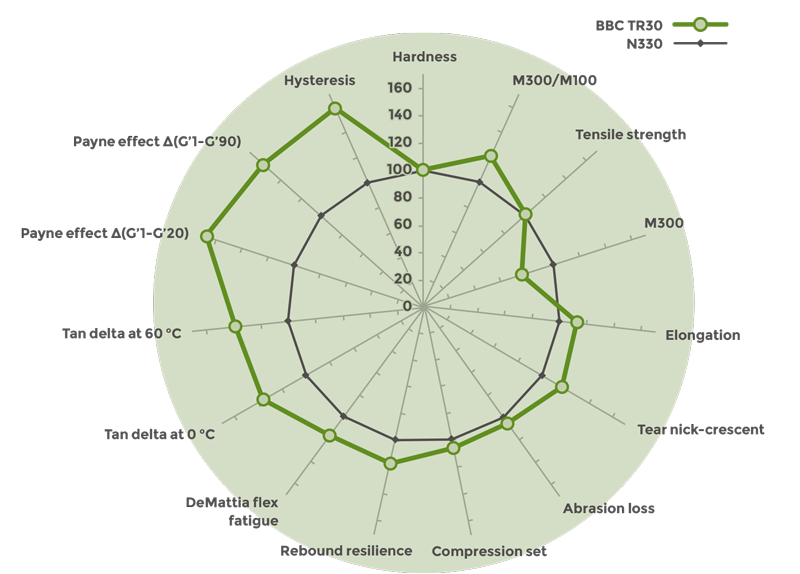

As a performance comparison example please refer to Fig 1 below. BBC T30 imparts overall higher mechanical reinforcement than N330 with lower modulus (M300) and a step-improvement in dynamic indicators.

- Due to its lower structure, BBC TR30 produces lower modulus than N330 at equal hardness and improved tear strength and a step improvement in dynamic performance.

- Its combined high surface area and low structure compared to N550 impact negatively on profile surface glossiness and as such BBC TR30 is only recommended for substituting N550 in EPDM hose extrusions where surface appearance is not critical. Surface glossiness improves a lot in highly loaded compounds (> 160 phr) due to the resulting dilution of the polymer content.

- With respect to flex-fatigue – it is well known that this is negatively influenced by the presence of grit (oversize particles) that is often present in (un-milled) furnace carbon black grades. As Black Bear mills all of its products to very fine particle size distributions (e.g. BBC TR30(S) milled to D99 < 3µ; D50 < 600nm), there are no oversized particles present – so completely grit free.