Black Bear opportunity: reduce hysteresis (via very low tan delta and Payne effect) and improve flex fatigue whilst maintaining or increasing mechanical performance

Introducing Black Bear’s grades in belt compounds will provide excellent tensile strength, high resistance to abrasion, cut and tear. At the same time dynamic properties such as flex fatigue, Payne effect and rolling resistance will drastically improve. Low hysteresis will reduce heat buildup in the skim. Overall reduced hysteresis will lower the total energy input for the conveyor installation.

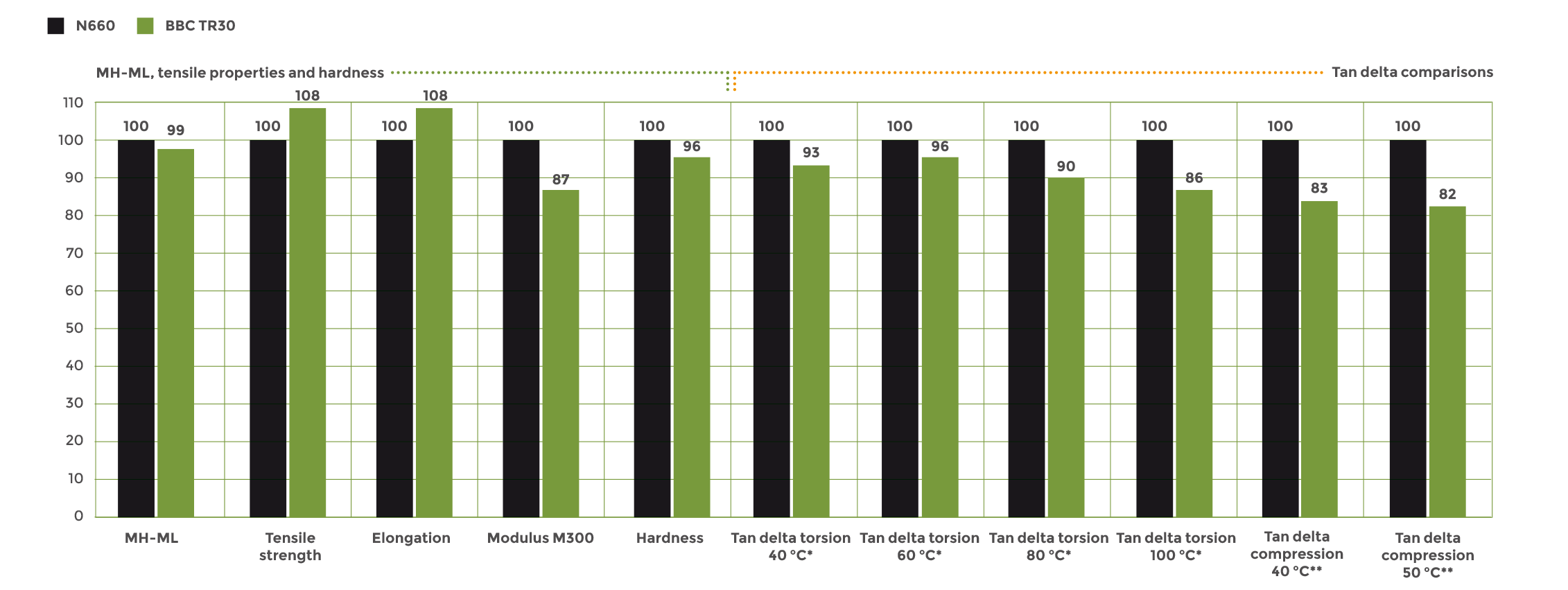

Generally, high reinforcing blacks are used for the cover compounds in order to ensure good wear resistance. The downside of these kind of blacks is their poor dynamic Performances. Black Bear’s carbon blacks uniquely combine good mechanical and dynamic properties (see figure to the right).

Hysteresis/modulus comparison against N347, N330 and blends with N330 in a 60 ShA natural rubber recipe

Black Bear’s products display a very unique combination of very low tan delta values in compression and torsion, very low Payne effect (comparable or lower than N660) combined with a high mechanical reinforcing index (M300/M100 ~ 5.4). This is the result of a medium/high STSA surface area combined with a low effective volume fraction and a uniquely broad primary and aggregate size distribution.